07

07-2022

DAT provides drive control solutions for the CVT laboratory at Ho Chi Minh City University of Technology and Education

To support the training of high-level personnel, DAT has designed a solution for the belt testing model at the Continuously Variable Transmission (CVT) Laboratory (Bosch Transmission Lab) at Ho Chi Minh City University of Technology and Education.

The CVT Laboratory project is sponsored by Bosch Group for Ho Chi Minh City University of Technology and Education with an estimated cost of about 2.5 billion VND. The project includes one CVT gearbox model, one belt testing system in the CVT gearbox, one practice and research room, and other teaching support machines and equipment. Among these, DAT is involved in designing the solution for the belt testing model.

Once operational, the CVT Laboratory will help students access the current technologies in the market, meet job requirements after graduation, and have more career development opportunities.

The continuously variable transmission belt is one of the important components that helps cars run smoothly. Based on Bosch’s requirements, DAT engineers proposed an effective solution for the belt testing model in the CVT gearbox, which meets the applicability in the field of drive technology research.

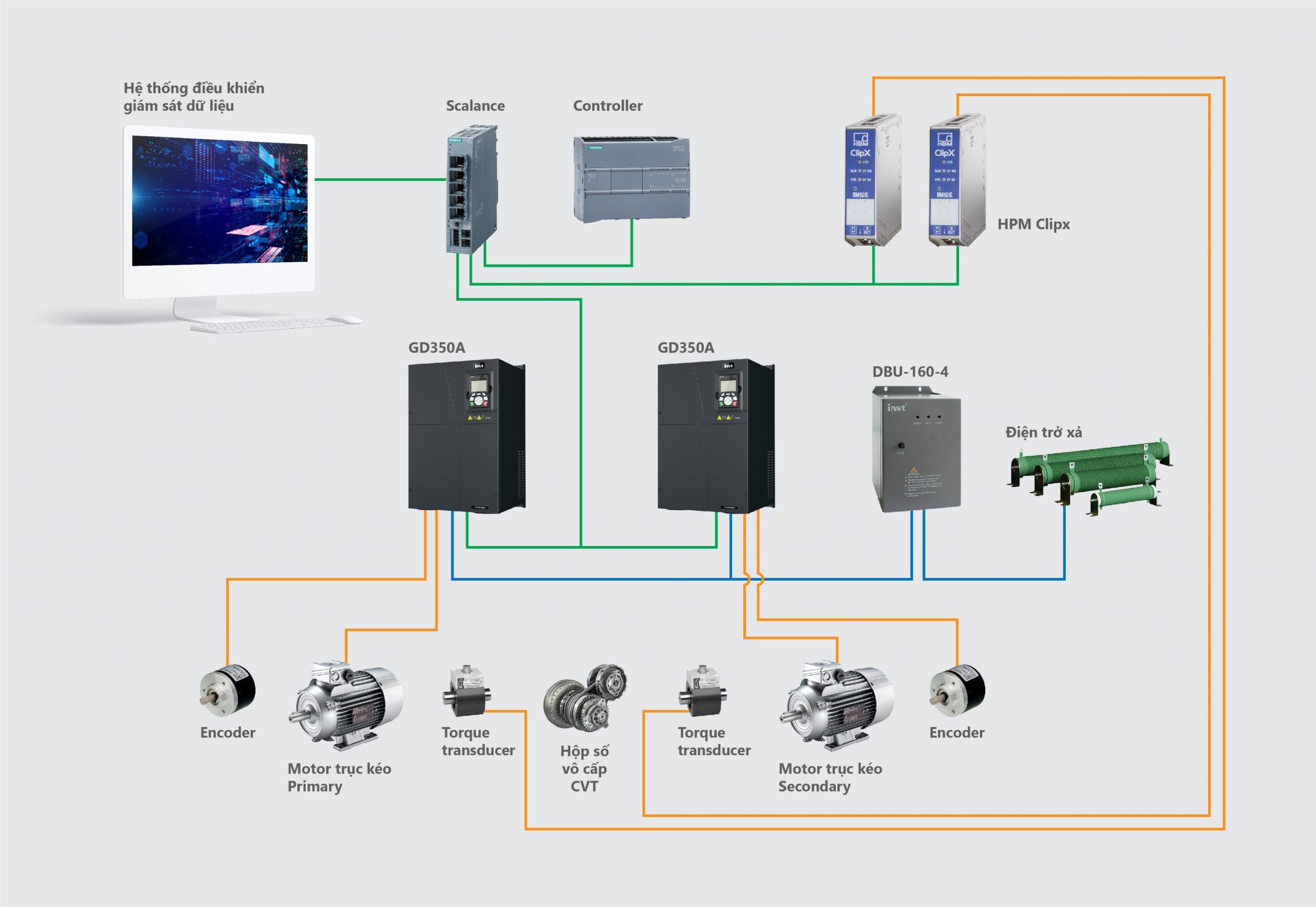

Accordingly, DAT provides a system consisting of:

- GD350A inverter connected to a PLC via high-speed Profinet communication, controlling the speed and torque of the Primary and Secondary shafts in a closed loop.

- PLC system connected to the server via Modbus TCP/IP communication, allowing easy control and monitoring of the system as well as easy adjustment of torque, speed, and control modes.

- HPM CLIPX units receiving torque signals at the Primary and Secondary shafts. The PLC connects with two HPM CLIPX units via Profinet communication, collecting data from torque sensors.

- Siemens SCALANCE industrial network devices that allow the system to be expanded.

- ABB motors with high inertia, integrated with encoders suitable for torque monitoring and speed control.

Through this system, instructors and students can perform various types of tests, analyze data, and easily understand the operating principles of the CVT belt.

The demand for highly skilled mechanical engineers is increasing as the Automotive and Supporting Industries are rapidly developing worldwide. By participating in this project, DAT aims to contribute to creating a favorable environment for training high-quality human resources in the future.

Currently, DAT is the leading provider of automation and renewable energy products and solutions in the Vietnamese market. To obtain our solutions that enhance operational efficiency and experience our superior services, please contact our Hotline 1800 6567 (toll-free).